What will you need?

In the beginning a few tools. They cost me around 400PLN (around 95EUR or 120USD), majority of which is the cost of soldering station.

I'll describe different types of soldering irons, guns and stations, and in next posts I'll continue the topic with some indispensable and other useful but not always necessary items, trying to give you as much information as possible and allow you for choice of cheaper or better options.

Unfortunately - with soldering gear - especially soldering irons/stations quality very often goes together with price ;)

1. What is a soldering iron?

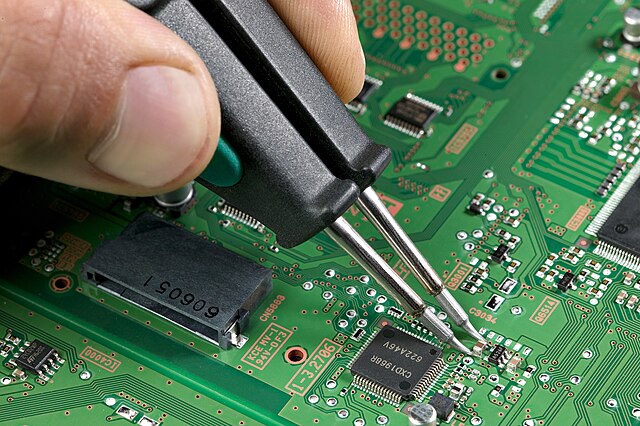

In a quite obvious way - the most important piece of whole puzzle, indispensable in one or other form for soldering. It heats up solder (e.g. tin alloy) so that it is possible to connect pieces being soldered with the solder, or so that it is possible to pull out a component we want to replace or save for later use (e.g. from a circuit board which is broken and which we don't want to repair).

However there are many kinds of tools used for soldering on the market, of countless brands. In addition to that even experienced people working with electronics argue which are best to be used. Some say that transformer soldering gun is great for electronics, others that on the contrary, only heater soldering iron is good.

The truth is, that if someone uses one kind very well and doesn't know how to use the other - in fact it is much better for him to stay with one he likes more - it works best for him. I will show you my own opinion, trying at the same time to shed some light on the topic, in a possibly objective way.

a) Transformer soldering gun

Soldering guns are popular because of their high power (60-120W is a standard), thanks to which they heat up very fast - in a matter of seconds. They cool down quite fast too, which is good e.g. while soldering inside a car or in other place where it is hard to safely put away a hot soldering tool.

Newer ones usually have a small lamp illuminating the place being soldered, and often power switches with a few power levels.

Their drawback is lack of exact temperature control of their tip - people experienced in their use can 'click' the soldering gun so that the temperature is kept in optimal range during longer soldering, that however requires a lot of experience in working with the soldering gun.

Most of people working with electronics don't recommend transformer soldering guns because of that, especially to beginners - it's too easy to overheat electronic components and destroy them, too easy to burn the circuit board, too easy to let the tip cool down too much in an inappropriate moment causing soldering errors if you don't have a lot of experience in using the soldering gun.

Because of their main piece - the transformer - the soldering guns are heavy. They are many times heavier than heater soldering irons. And even quite comfortable pistol grip doesn't help when you work for a longer time - your hand will simply start hurting.

Additionally, high current flow causes emission of strong electromagnetic field around the tip. That means that small metallic components may get attached to the tip, which sometimes may be useful, usually isn't though. Moreover, some more complicated electronic components may be susceptible to strong electromagnetic fields and may get damaged.

I personally don't recommend a transformer soldering gun for electronics.

Indeed, it is good to have one, even the cheapest one in stock, because it is useful if you want to solder thicker wires or you want to solder a radiator to circuit board (some radiators have legs allowing soldering them to boards) - then with large heat capacity of soldered components, the high power will be very useful allowing to heat them up properly. Besides that, as I already mentioned, they can be comfortable in use in places where it is hard to put away safely a hot soldering tool.

The fact that it is very easy to make additional simple tips for them is also an useful trait - you just need to take a piece of copper wire of diameter proper for that soldering gun, cut it and bend into a proper shape. That means that used up tips (about how they get used up I'll write in next parts) are easily replaced with cheap, even if less durable, equivalents. Thanks to that you can also make a bit suitable for your needs - for example bending it so that it fits to the legs of integrated circuit or other component you are desoldering - so that you can heat them all up at the same time.

It is good to have one of those in stock - for special tasks ;)

I own a transformer soldering gun bought in a construction supplies market for about 20PLN (~5EUR/6USD).

It works well for my uses (even though I bought it slightly damaged - it's good to inspect well the tools you buy in such places).

b) Heater soldering iron

Their main piece is a resistive heater which heats up when the current from the mains socket or (more often) power supply flows through it and the heat is conducted to the tip.

If we speak about the simplest heater irons, this is pretty much their whole construction - however they aren't best for electronics - they don't have adjustable tip temperature. I don't recommend buying in supermarkets or construction supplies shops etc. those cheapest versions even though their prices are tempting.

Better soldering irons have a temperature regulation. Easiest way of regulating it is a simple potentiometer which allows a skilled user to adjust the temperature - however this isn't the solution that is easiest in use because you need to have enough experience to feel how to adjust the power well to the size of piece being soldered, to achieve the required temperature.

Soldering stations are better, equipped with more precise temperature regulation - with a temperature sensor in the soldering iron - but about those in a moment.

The advantage of soldering irons is that they're very light in comparison to soldering guns, so in a longer run, much more comfortable in use.

Temperature regulation allows them to keep much more stable tip temperature, thanks to which it's easier to avoid soldering errors.

They have lower power (often 15-60W), which isn't a drawback though, because in electronic uses we don't need so high power with most components, and for ones that could need it, we can turn the temperature up or use cheap transformer soldering gun we have in stock ;)

Another advantage is lack of the strong electromagnetic field.

Additionally the fact of using power supplies in most soldering irons means that we don't hold in our hands something something connected to dangerous 230V or 130V mains, and that the iron's power cable isn't under such voltage - which is important in case of some malfunction or accidentally burning the power cable with soldering tip.

Safety first - you can buy new fuses, new soldering tools, but you probably can't get a new life.

Unless you're a cat. And have 9 of them.

Their drawback are usually more expensive soldering bits (especially for brand, more expensive and better soldering irons and stations). In addition it is much harder to make one yourself, so instead you need to tinker a lot or just buy new ones dedicated for various uses.

Other drawback is longer heat up period, however usually reaching working temperature doesn't take much over minute - two, so after turning it on you can take care of getting everything else you'll need ready, and the soldering iron will manage to reach needed temperature in that time.

There are much bigger versions, with much higher power reaching 400-500W and a large bit which gives them high thermal inertia, but they don't have use in electronics - they're used for soldering plates, pipes and such, so we won't concern ourselves with them here.

c) Soldering station.

Thanks to that we can set temperature we want and the electronics will take care of it so that it doesn't drop too low during soldering, nor rise too much. We reduce risk of not heating well enough as well as of overheating the solder and components being soldered as long as we use proper soldering technique - about which later.

More advanced stations have alarms - visual and/or sound - informing about decreasing tip temperature below set level, which may happen while soldering components with high heat capacity (large wires, radiators). There also are stations with vacuum pumps - thanks to which their soldering irons can use special tips removing the tin during desoldering.

Decent station without additional bells and whistles, and just with a heater soldering iron (mainly Xytronic brand - chinese, but quite good one, from the middle shelf unlike other chinese brands) start at around 180-200PLN (43-47EUR/54-60USD).

Do not buy cheaper stations or you'll have to pay twice, unless you plan on soldering only a few components once per month. And if you're really, really tempted, always check what opinions does given equipment have in internet - you probably won't want to buy it anymore.

Good brands (probably best known Weller for example) start at about 1000PLN (240EUR/300USD) or somewhere around that.

Of course it's always worth to read what its users write about given model to make sure that you are really buying what you need.

Me, as I was going for more economic option, but at the same time I didn't want to buy something I'll want to change to something better in a short while, I've bought LF-369D from Xytronic - medium shelf, for about 190PLN (45EUR/56USD) if my memory serves well.

Better, more expensive and advanced soldering stations often have also either in standard or as an additional option to be connected to them many additional devices:

- Hot Air soldering gun/iron.

This is a tool allowing directing a hot air flow (a few hundred Celsius degrees, up to around 800 Fahrenheit possibly) onto components being soldered/desoldered. Often it is a part of more expensive soldering stations, it also is available as separate hot air soldering station without soldering iron.

It should not be mistaken with heat guns used for stripping paint, dry out wood, shrink plastic packagings etc. which usually use much higher temperatures - using a heat gun on electronic components by people trying to save some money on equipment usually ends tragically for those components and printed circuit board. I've seen opinions that it can be done - but you can also solder with a piece of thick nail put into flame of gas oven until it's heated enough to melt tin (actually that's how first soldering irons worked).

Unfortunately, with tools for electronics, very often price means quality.

Hot air stations make work much easier with components other than through-hole ones. Soldering and (especially) desoldering of SMD (Surface Mount Device - more about electronic components and their casings will be in an article about them) is much easier using hot air. It is indispensable in soldering some components which, depending on casing, may not have any 'legs' at all, nor other leads which can be soldered from outside, only leads underneath - those can't be soldered in home conditions otherwise than with hot air (industrially soldering furnaces are used). Similarly it may be impossible to dismount various integrated circuits, even through-hole or SMD, without damage, when they are glued to the circuit board, which sometimes makes it impossible to dismount them without hot air.

Usually such stations have an option to adjust temperature and airflow strength, which with skillful use solves problem of blowing other components away during soldering, which is a problem unskilled users sometimes stumble upon. There are also available overlay pieces allowing precise heating of given component without big influence on surroundings.

For beginner or person who doesn't plan to work in nearest future with components other than through-hole ones - it isn't a compulsory tool.

If you think of electronics seriously though, sooner or later you will need a hot air station - so don't duplicate my mistake and buy a decent station with both heater soldering iron and hot air. Usually such set is slightly cheaper than buying two soldering stations separately, and at the same time takes a bit less space on the table.

- Soldering tweezers.

|

| Soldering tweezers. Source: Wikipedia |

They are supposed to be useful in soldering and desoldering SMD components.

I've never used them myself, but it seems to me (and such opinions I mainly read in internet), that it doesn't give you anything which you can't achieve similarly easily with soldering iron or hot air. Maybe it's a bit more comfortable for desoldering SMD, but I doubt it's enough to invest in it. Unless it is in a set you want to buy anyway.

- Heater/hot plate.

This is a surface connected to soldering station (or standalone) heating up to given temperature - usually around 150 Celsius (300 Fahrenheit) degrees.

It's purpose is preheating circuit board from below, while we'll be soldering/desoldering it using hot air from above.

It helps to avoid mechanic strain connected with uneven heating, especially dangerous for large integrated circuits which can be damaged during mounting/dismounting without a heater.

Many people instead of buying dedicated heaters for electronics, which aren't very cheap (200-400PLN here, making it ~48-96EUR/60-120USD) they use e.g. electric grills (costing around a quarter of that), which also have heated plates which heat up to set temperatures - which can't be adjusted so precisely for electronic purposes though, so it might be worth either to check what temperature it may achieve and sustain, or use an equipment checked already by others (it's easy to find in internet). Or make a temperature control circuit for it - which requires a bit of effort (isn't that hard though).

It is rather an additional piece - not required for beginning electronic.

- Soldering pot.

Just as the name suggests - it is a small 'pot' with a heater heating it up to solder melting temperature. In electronics it is moderately useful. It can be a standard part or can be bought as additional piece for some soldering stations, or as a separate device.

Its main use for us is ability of tinning (more about it later) very quickly many wires or other components, even very thick ones in a short time.

The cost depending on size (and brand) is around 80PLN (19EUR/24USD) and higher. I can't recommend anything specific because I don't use it - for tinning larger pieces a transformer soldering gun is enough for me as I neither do it for the living nor I need to tin a lot of components in a short time.

It probably isn't needed for a beginning electronic - unless you know that you'll be tinning large amounts of cables. If yes, then it will definitely make your life easier.

- Servicing power supply.

Some stations also have power outlets, usually with 5V, 12V, 24V and mass/grounding or with just a few of those.

It can be useful if you drive with such equipment to customers and/or don't have separate power supply allowing to test various circuits without wasting time seeking for various external power supplies you'll need.

I doubt it is very useful for a beginning electronic (especially that very probably as one of first more serious projects you'll be making your own servicing power supply made from some old computer power supply or something similar). So if there is that functionality - it's cool, but I wouldn't choose a station specifically because of ability to use it as power supply unless you want to use it for driving to work in terrain. Or if you don't want to play with making your own cheaper power supply from computer power supply.

- IR, laser

I add it here pretty much as a curiosity, because it is an advanced and expensive equipment most electronics dream about, used mostly in industrial and/or precise and very specific fields (military, medical, space and other ones where very important equipment depends on it).

There are heaters using infrared radiation to heat circuit boards up, having similar functionality as regular hot plates/resistance heaters, but heat in a much better controlled, precise and in general better way ;P

There are laser soldering tools which heat solder with a beam of 5-30W laser (no, you can't make it from a laser pointer or a DVD laser diode), which allows for incredibly precise soldering.

d) Gas/propane soldering iron.

|

| Propane soldering iron. Source: Wikipedia |

What heats up the tip however is not electricity but burning gas. Usually it is regular propane gas you can buy in cans for refilling lighters (similar to spray cans, it's an expense in range around 15PLN - 3,5EUR/4,5USD per can).

It has in essence same functionality as a heater soldering iron, its major bonus however, and it's sense of existence in fact, is ability to carry it around - it's light and doesn't need mains socket to which you'd need to plug it in, at worst reloading it each 20min-1h (depending on model) with gas from the can.

Most such soldering irons have an ability to solder with tips heated with the flame, option to take off the tip and solder as with a burner (useful e.g. for soldering plates and other large pieces), and option of putting on it special nozzles for soldering with hot air - giving very big versatility to this portable device.

It isn't a first need equipment, but it is a very interesting alternative, especially if you plan on servicing in terrain, where not always is an access to mains to use electric equipment and/or you don't like walking/driving around with a lot of gear on you.

Similarly to heater soldering irons there are larger and more powerful versions for soldering gutters and large plates - which are eliminating soldering irons from that use exactly because of their portability, because they can be fed from portable propane cylinders, which may be important in places where it is hard to access mains.

That would be all about soldering tools. If I've missed something, you have any questions or just want to say what you think about this text - please write a comment ;)

In next part about fluxes - including best known rosin, and about types of solder - mainly about best known, tin alloys. They are just as indispensable as soldering tools above, so if you're interesting in it - keep reading ;)

Next part: 2.2 Soldering - Basics - Tin and rosin

Previous part: 2.0. Soldering - Basics - What is soldering?

Beginning: 1. Safety rules and hazards in electrics and electronics

No comments:

Post a Comment